The progress reports

Each week (hopefully) we update this page with new photos of instruments in progress. The updates will usually be on Monday.

We hope that you enjoy seeing the progress on your instrument and those of others who have them on order.

Week ending February 11, 2008

See last week, or next entry, or the index of other weeks for more pictures.

Things got a little frazzled last week, so we ended up with double this week.

The visiting HG that was in for repairs in the final stages of reassembling the keybox. This instrument went out the door this week, back to its owner.

On the Minstrel: sanding the angles on the peghead parts.

The Minstrel peghead parts glued together and ready to be final fitted and glued to the head plate.

The Minstrel body being glued to the hip blocks.

Gluing in the Minstrel head and tail blocks.

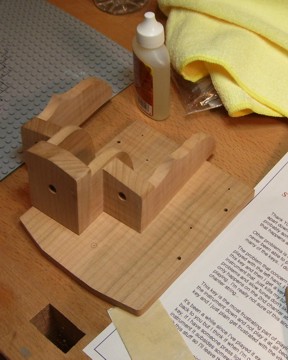

An experimental keybox

The words for the week(s) were "stock prep" for the run of Chinooks. Here are long boards that have been pulled from wood storage, waiting to be cut.

On the chop saw

Sides and backs ready for resaw

Resawn blanks - backs ready for glueup, sides ready for sanding preparatory to bending

Bending the sides

Putting the side in the mold

Gluing in the head and tail blocks

The bodies are stacking up...

More stock prep - these are keybox side blanks

And more keybox blanks

Making head blocks on the table saw

Gluing up a back set

An experimental wheel in "bondage", being temporarily bonded to the lathe backplate

One of our first instruments came back to visit, on its way to a new owner. Back when we made it, we didn't use serial numbers. If we had, this would have been 002 VG 002, for our second Volksgurdy. Instead we gave them names from ancient history. This one was named "Olympia".

One interesting aspect of our job is making molds for our cast parts. It turns out that Legos (TM) are a great way to make the mold boxes for pouring the mold material into - they're modular, easily available, you can make any shape you want, and they're fun to play with! We got the idea from the Smithsonian, where they use the technique for making mold boxes for casting small fossils.

The parts came from Oneida Air to connect the new sander (named Harris) to the dust collector (named Monica). It's not all in place yet, but I at least got it hooked up so that we have a blast gate working on the sander.

Of course not everything went perfectly - the bandsaw developed an unfortunate drift, so needed the blade changed and the lower bearing replaced. Delta makes good tools, but sometimes they are a little short-sighted on ease of service - this is the disassembly I needed to do to get the bearing out.

We had two more equipment failures: a piece of casting equipment developed a potentially explosive leak, and the radio-controlled relay for Monica the dust collector had a meltdown. Luckily there were no injuries or damage, but we'll have to fix the equipment to get it running again. (Maybe it's because Mercury is in retrograde...)

See you soon!

Thanks for watching - tune in next week!

Please contact us if you have comments or questions about this page or other pages on this site.

Alden and Cali Hackmann

Olympic Musical Instruments

Beati illi qui in circulum circumeunt, fient enim magnae rotae.

© Copyright 2000, 2005, 2008 Olympic Musical Instruments.

Please ask for permission to use material from this site. Thank you.